The Projects: From PROGRASS to the Circular Carbon Economy

Since 2008 the PROGRASS community has developed a number of research-practice projects based on the utilisation of unused grasslands and biowaste in Europe mobilising more than 15 Mio € in Research and Development for a Climate Friendly Circular Economy.

Our initiative is based on an approach which we called IFBB “Integrated Fuel from Biowaste and Biogas”, which was based on the works of Prof. Konrad Scheffer in the early years of the new millennium. The approach facilitates the conversion from grass wastes and landscape materials into energy.

The first PROGRASS project designed by Prof. Michael Wachendorf and Dr. Tim Scholze, upscaled the IFBB method to demonstrator size and piloted it in four European regions in Germany, Wales, Estonia and in a holistic approach which involved local farmers and nature protection areas.

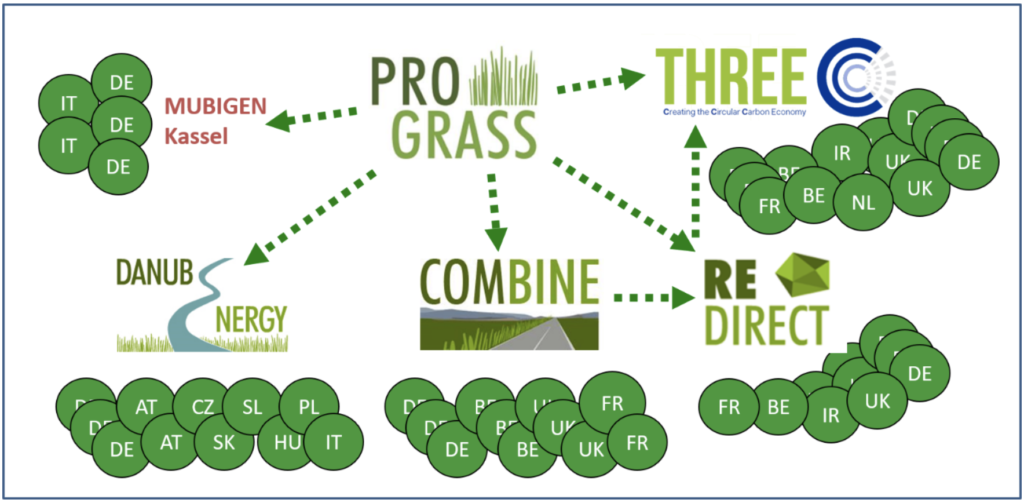

PROGRASS was transferred to different European regions, firstly in the DANUBENERGY project, involving 8 regions in riparian flood-plans from Central Europe from Austria, Czech Republic, Italy, Slovenia, Hungary; Poland, Germany and Slovakia. In parallel, the COMBINE project focused on grass and landscape management materials covered from roadsides and verges in Germany, France, Wales and Belgium. Both projects were funded by INTERREG programmes. At that time, a first large scale IFBB plant was introduced at the Environmental processing plant of the city of Baden-Baden by Bernhard Schäfer, securing the upscaling to full scale and a high Technology Readiness Level.

Meanwhile our teams also researched and developed recovery and energetic conversion concepts for urban biomasses in the project MUBIGEN, funded by the European Institute of Technology (H2020) and analysed their potentials in two municipalities in Kassel (DE) and Reggio Emilia (IT).

In 2016 the approach was extended from a solely energetic conversion to a product development pathway by adding a pyrolysis stage to the IFBB technology. This way, for the first time, activated charcoal could be produced from different biowastes stemming from grass, wood and biowaste from households. This project, called RE-DIRECT, was carried out by a multi-stakeholder partnership from universities, research and education institutes and energy counselling agencies from DE, UK, IR, BE and FR. The conversion into carbon feedstock was extensively piloted and analysed and, thanks to INTERREG NEW funding a large scale urban and a small scale rural pyrolysis plant could be installed in Baden-Baden (DE) and Bangor (Wales).

The current project THREE C (2020-2023) addresses the challenge to stimulate innovations and innovative capacity of SMEs, creating business and entrepreneurship in the new field of the Circular Carbon Economy.

7 regional CC (circular carbon) hubs will provide support for (foremost small and new) entrepreneurs and SME working in the circular carbon and charcoal sector, incubating their business development.

A central CC lab will be installed to cover different aspects of charcoal analytics and provide recommendations on product composition and a database on different charcoal qualities and eventually a CC quality label.

Eventually, with the THREE C project PROGRASS will become a CC-Net – a European network which will render services to those regions that want to become active in the Circular Carbon Economy.